Originally published in Manufacturer, ARB’s Manufacturing Industry newsletter.

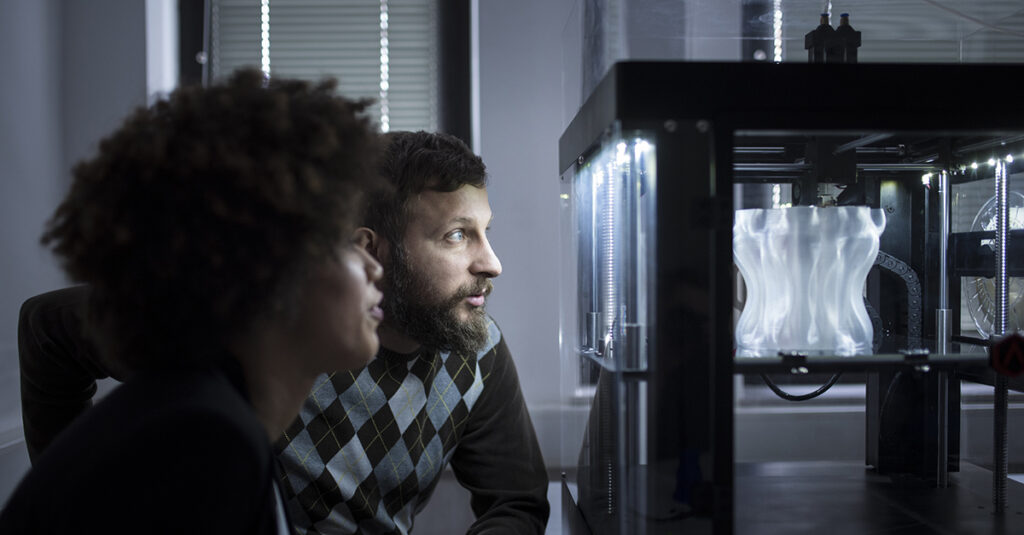

Amazingly, 3D printing has existed for more than 40 years. Recent improvements in the technology have increased its acceptance as a speedy, cost-effective tool for creating product prototypes. Is it right for your manufacturing business? To answer this question, consider the following eight advantages of using 3D printing:

- Cost reduction. 3D printing is generally faster than traditional production methods, in part because it avoids the need for molds, dies or fixed tooling. It’s also highly automated, reducing staffing costs — and occupies far less space, reducing facility and other overhead costs. It allows manufacturers to print on demand, meaning you’ll no longer have a need for large stock inventories.

- Waste reduction. 3D printing uses only the material needed for the part. So, it’s also known as “additive manufacturing” — that is, it creates products or parts by adding materials layer by layer. This results in far less waste than traditional “subtractive” or “reductive” manufacturing methods, in which a product or part is created by removing material from a block of raw material.

- Greater customization. By eliminating the need for fixed tooling or molds, 3D printing opens the door for customization on a mass scale. Each product or part that a 3D printer creates can be different, allowing a manufacturer to offer customized designs and a variety of materials to meet customers’ specifications.

- Increased speed and efficiency. 3D printing eliminates the need for time-consuming toolmaking and fabrication processes. It allows manufacturers to develop, modify and create prototypes faster and at a lower cost. This allows manufacturers to streamline product development and production, bringing products to market more quickly.

- Enhanced quality and consistency. 3D printing makes products and parts using digital designs and specifications. This removes human error from the equation, enhancing the quality and consistency of the manufacturing process. The 3D process also makes it far easier and cheaper to modify designs and adjust the manufacturing process to address quality issues.

- The ability to make complex products. 3D printing gives manufacturers the ability to make complex products or parts that may be difficult — if not impossible — to make using traditional manufacturing methods. For example, it may be possible to create a single, highly complex part that otherwise would have to be created by welding together separately machined components — a time-consuming and error-prone process.

- Better customer service. With traditional manufacturing methods, implementing product enhancements can take a long time. In contrast, 3D printing makes it possible to make product enhancements and deliver them to your customers quickly. It can also improve product maintenance and support by enabling manufacturers to produce spare parts on demand, avoiding the need to maintain spare parts inventories.

- Cost-effective low-volume production capabilities. 3D printing can make low-volume production runs less expensive than the cost of using traditional methods.

While the future is bright for 3D printing, there are still some constraints. For example, many 3D printers tend to be small, so manufacturers may still need to combine 3D components with larger parts after printing. In addition, unlike most other manufacturing, the cost per unit won’t be reduced significantly when you scale up printing for mass production. You’ll have to balance this against other cost-saving benefits of 3D printing.

Watch for Opportunities

As the quality of the hardware and software improves and the cost of materials suitable for 3D printing decreases, use of this technology in the manufacturing process will likely take off. Be sure you’re ready when this technology is right for your situation. Your CPA can help you determine whether the costs of purchasing 3D printing equipment will pay off over the long run.

This publication is distributed with the understanding that the author, publisher and distributor are not rendering legal, accounting or other professional advice or opinions on specific facts or matters, and, accordingly, assume no liability whatsoever in connection with its use. ©2025

Manufacturing Team Spotlight

Samantha Pedersen joined ARB in 2004 and currently serves as a director. She provides business advisory and attest services primarily to credit unions, commercial businesses, manufacturers, and nonprofit organizations. Sam is responsible for coordinating the training and implementation of Financial Accounting Standards Board (FASB) updates at ARB.